RIBBON STRIP – COLORBOND METALLIC

Innovation and sensability

The Ribbon Strip in Metallic COLORBOND® is ideal where innovation and sensibility on a project is of the utmost importance. The predefined perforated fixing strip ensures speed and ease of laying panels whilst allowing for expansions and contraction for varying weather conditions.

The male-female relationship where the over seam snaps securely into place onto the under rib reduces labour coupled with the lightweight nature of each panel make the Ribbon Strip, commonly known as ‘Nail Strip,’ an economical system for commercial, industrial and residential environments.

The direct attachment of these panels simulates the look of a mechanically seamed panel without the use of concealed clips or the additional operation of seaming. Due to this process it is less likely to be used in high wind areas as more attachment points would be required to satisfy uplift pressures.

RIBBON STRIP – COLORBOND METALLIC

Ignite architects imagination

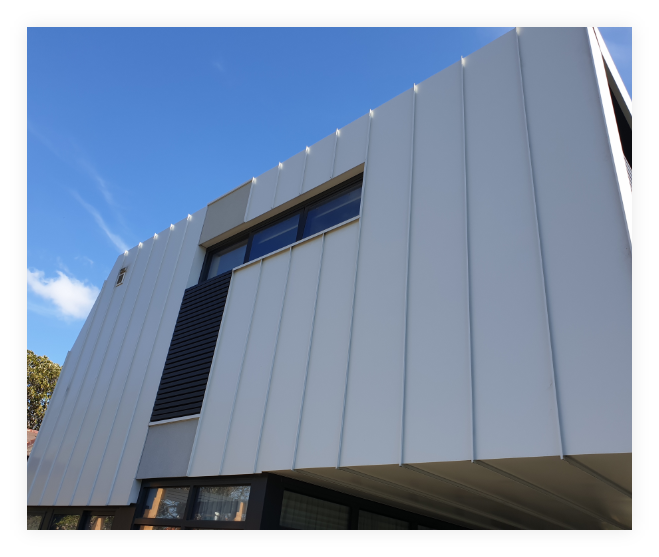

The inherent flexibility of COLORBOND® Ribbon Strip enables architects to create unusual forms and shapes that can appear modern or traditional depending on their intent. The design flexibility offered by the adjustable tray width of the Metallic COLORBOND® Ribbon Strip ensure seamless interaction with windows, doors and internal / external corners with minimal use of bulky flashings letting the cladding speak for itself.

RIBBON STRIP – COLORBOND METALLIC

Performance and variety

The use of Metallic COLORBOND® Ribbon Strip in larger construction has taken hold since 2015 with the retirement of the colour range like Citi and Façade and the introduction of Metallic Galactic, Cosmic, Rhea, Astro, Aries and Celestian. These natural colour finishes reflect the natural the environment. Coupled with the thin lines of the Ribbon Strip offers a lightness in form that is sympathetic to its local surroundings. The Ribbon Strip profile can be run in multiple widths and staggered to minimizing a buildings scale by visually softening its edges and allowing it to blend in.

25mm Ribbon Strip

Material Thickness 0.55mm

| Centre to Center Distance | 195 | 295 | 495 |

| Length | 500mm to 6000mm | ||

| Rib Height | 25mm or 38mm | ||

| Fixing on perforated stip | 330mm | 330mm | 330mm |

| Substrate | WALL = 15mm ply – ROOF = 19mm ply | WALL = 15mm ply – ROOF = 19mm ply | WALL = 15mm ply – ROOF = 19mm ply |

| Panel Weight per m2 | 6.8 kg | 6.0 kg | 5.4 kg |

38mm Ribbon Strip

Material Thickness 0.55mm

| Centre to Center Distance | 165 | 265 | 465 |

| Length | 500mm to 6000mm | ||

| Rib Height | 25mm or 38mm | ||

| Fixing on perforated stip | 330mm | 330mm | 330mm |

| Substrate | WALL = 15mm ply – ROOF = 19mm ply | WALL = 15mm ply – ROOF = 19mm ply | WALL = 15mm ply – ROOF = 19mm ply |

| Panel Weight per m2 | 8.0 kg | 6.7 kg | 5.7 kg |

Facade

- From 60 ° to 90 °.

- Both renovations and new buildings.

- Useable length : up to 4 m.

- 2 types if installation: Vertically or Horizontally.

Roof

- All types of roofs.

- All shapes: flat, curved, concave, convex, conical, domes.

- Pitches: Minimum pitch 3° (5%).

Support

- 19 mm plywood rigid and continuous, with a minimum 40 mm ventilation cavity that is unobstructed.

- Rest on at least 3 bearing structure elements.

- Have no protruding elements on the support.